Sand Stabilisation Hafr Al Baten – Kingdom of Saudi Arbia

Project: To prevent sand incursion on the Saudi Arabian Rail North – South line.

Project Objectives: Stabilisation of Railway berms on the North-South line at Hafr Al Baten. This project was carried out using TerraFirma TF-2000 Polymer Technology to stabilise select areas of Railway protective berm. A Topical application was chosen to penetrate deep into the sand and create a hard, wind resistant, crust. The polymer treated surface will keep the sand in place and reduce active migration. TerraFirma Polymer Technology has been tested to withstand surface wind velocity greater than 100 miles per hour with no deterioration of surface crust. Project and TerraFirma supplied Polymer Technology successful.

Equipment: Water Truck, Spray Truck with Pump and Dual Hose Attachment.

Application Specifications: Topical Application.

Road Construction Madain Salih – Kingdom of Saudi Arabia

Project: To improve road conditions on a UNESCO World Heritage site.

Project Objectives: Construction & Stabilisation of 10km x 12mtr Multi-Layer Road and Parking Lot (s) at Madain Salih (Al Hijr Archaeological site). This project was carried out using TerraFirma supplied Polymer technology to reduce dust emissions and retain the natural beauty of this UNESCO listed site. Project and TerraFirma supplied Polymer Technology successful and approved by Saudi Ministry of Works and UNESCO.

The laboratory tested increase in CBR value between the polymer treated soil and untreated soil was 18%. The polymer treated soil also showed a 74% improvement over untreated soil in dry unconfined compressive strength (UCS). When tested for wet UCS values, the untreated soil, after soaking, had zero strength and became completely dissolved in the water bath. Soaked samples of soil treated with Polymer Technology remained solid and had an average UCS of 471 psi. Polymer technology was accepted by the Saudi Ministry of Works as a preferred road construction method for highly sensitive environmental areas such as this UNESCO World Heritage Site.

Equipment: Road Grader, Water Truck with Pump and Hose Attachment, 10t Single Drum Vibrating Compactor.

Application Specifications: Infused application and a topical seal coat.

Dune Stabilisation – Kingdom of Saudi Arabia

Project: Ministry of Transportation. Harad – Al Batha Highway.

Project Objectives: Stabilisation of roadside berms on the Harad – Al Batha Highway. This project was carried out using TerraFirma TF-2000 Polymer technology to prevent the resident dunes drifting and blocking this main Riyadh – UAE Highway. Project and TerraFirma supplied Polymer Technology successful and approved for general stabilisation use within the Ministry of Transportation.

Equipment: Water Truck, Spray Truck with Pump and Dual Hose Attachment.

Application Specifications: Topical application.

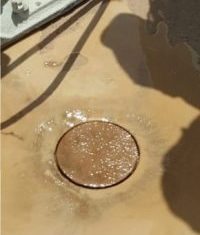

Pipeline Stabilisation – Kingdom of Saudi Arabia

Project: To Stabilise and Protect Pipeline Protective Berm.

Project Objectives: Stabilisation of protective pipeline berms in the Riyadh area. This project was carried out to protect a newly built 77km pipeline using TerraFirma TF-2000 Polymer technology to stabilise the protective berm.

Equipment: Spray Truck with Pump and Hose Attachment.

Application Specifications: Topical application.

Desert Road Construction – Sharjah, UAE

Project: To create a hard-wearing desert road at a Private Park.

Project Objectives: Construction & Stabilisation of 8mtr x 75mtr access Road at this Private Park in Sharjah, UAE. The project was carried out using TerraFirma TF-5000 Polymer technology to reduce dust emissions and retain the natural look of this area.

Equipment: Road Grader, Water Truck with Pump and Hose Attachment, 20t Single Drum Vibrating Compactor.

Application Specifications: Infused application and a topical seal coat.

Marl Soil Stabilisation Tubli – Kingdom of Bahrain

Project: To improve road conditions on an industrial road.

Project Objectives: A section of the road was selected to evaluate Polymer Technology for road stabilisation using marl and sand materials. The road base material used for construction was a 3:1 mixture of sand and marl, a locally imported calcium carbonate deposit. Marl is typically blended with sand to create structural road base material, Marl loses much of its physical strength when wet and requires stabilisation to maintain bearing capacity and hardness. Polymer Technology was mixed with base materials creating a water resistant, wear course surface with excellent strength and resistance to surface deformation.

Equipment: Road Grader, Water Truck with Pump and Hose Attachment, 10t Single Drum Vibrating Compactor.

Application Specifications: Infused application and a topical seal coat.